Cabinet vibration reduction system manufacturers: common problems in the application of cabinet vibration reduction systems

Add time:

2020-10-20 00:00

The scope of application of the cabinet vibration reduction system is very common, and the key is applicable to the seismic level of pipelines and machinery and equipment such as chemical plants, thermal power plants, chemical enterprises, smelters, etc. This field is a field with frequent safety accidents, so it is used in the whole process of application. There are many areas that must be paid attention to. Today, I will talk to everyone about what must be paid attention to during the entire application process of the cabinet vibration reduction system manufacturer.

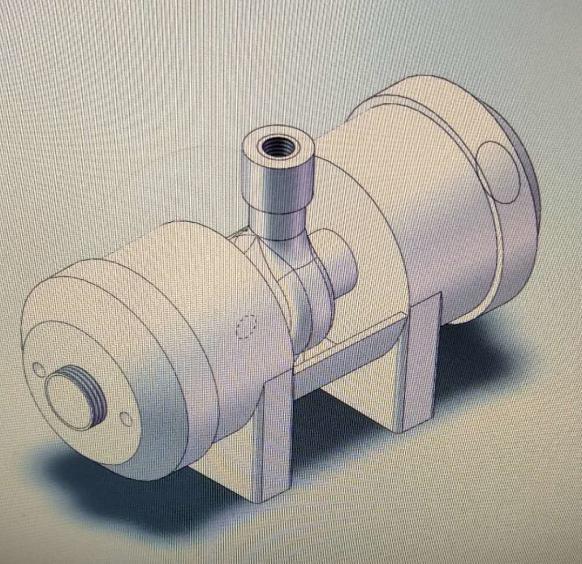

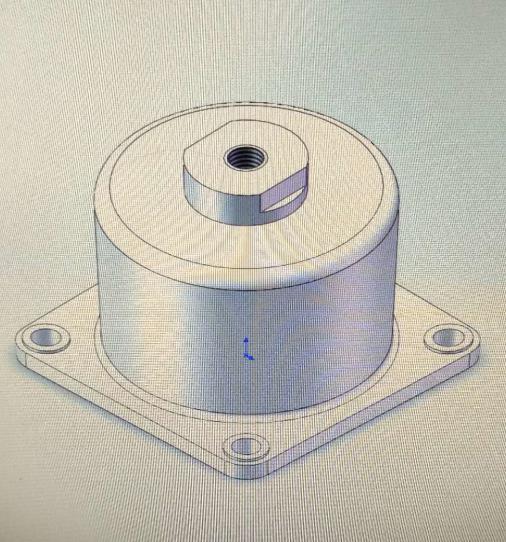

The cabinet vibration damping system is divided into suspension type and hoisting type. There is no doubt that the suspension type is compared with the hoisting type. There are a lot of common problems in the whole process of application. The first is how to prevent it from being invalid. Floating under the mutual effect of the circulatory system load and the magnetic material, and the elastic rupture caused by the mutual effect of the tensile ground stress and the erosive material. If the suspension system shock absorber bears unevenly, it will be affected by the entire operation of the machinery and equipment. Vibration and noise will be caused in the process, which will endanger all normal applications of machinery and equipment, and reduce the service life of machinery and equipment.

When using lifting-mounted cabinet vibration reduction system manufacturers, when the social development starts to work, it is necessary to check whether the spring yellow offset of the shock absorber meets the regulations. If the equipment is unevenly distributed, it can be based on the equipment The total weight of the cabinet plus 20% is used to calculate which category of the cabinet vibration reduction system is. According to the specific situation, the basis of the large positive and category is adopted. Berger based on the total output of the vibration reduction system software, which includes industrial equipment, base, The net weight of some pipes, cables, etc., and the specifications of their bases are used to clarify the specifications, model and total number of the shock isolator. The operating temperature of the product is minus 20°C to 80°C. It is inadvertently applied in a natural environment with strong acid and strong alkali gas When choosing products, choose carefully.

The cabinet vibration damping system can be properly overloaded when it is working, but it should not exceed 20% to 30% of the rated load. When the adjustable shock absorber is installed, if it is found to be basically not level, the anchor bolts can be adjusted to make If it is not for the anti-cutting shock absorber of the generator set, the protection equipment should be upgraded when the generator set is transported. The application of the cabinet vibration damping system manufacturer in the industrial production is very critical. It can not only improve the office environment but also upgrade the equipment. In the case of service life, so in the whole process of application, the actual operation should be careful and meticulous.